1. When the RichAuto A11 controller is powered up, the screen flickers or restarts automatically.

First, the power supply is insufficient. In this case, check if the switching power supply of the machine is normal. If not, replace the high-quality switching power supply.

After excluding the previous factors, check if the external supply voltage is unstable. If not, increase the voltage regulator filter to solve.

In addition, if the machine is powered and powered by a computer with a USB cable, it may be that the internal power chip of the handle is aging. The power chip replacement is required at this time.

Also, use the mobile phone charger (standard 5V) to power the handle through the data cable. That is a dual power supply. But this is only a temporary solution.

2. The RichAuto A12 handle cannot set the workpiece origin during normal operation.

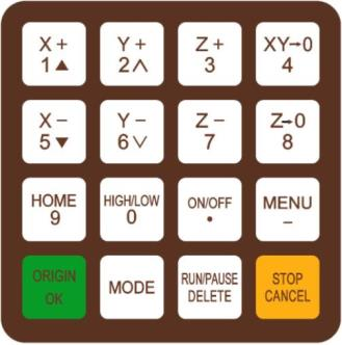

First, the user may enter the mechanical coordinate system due to a misoperation. At this time, check whether AX, AY, and AZ are displayed on the left side of the screen. If yes, press the “MENU” + “X+1▲” button to switch to the workpiece coordinate system interface.

Also, it may be a button problem. Try the steps to check if it is normal: SYSTEM SETUP-Buttons Check.

3. An assertion error occurred during the processing of the RichAuto A15 handle

Generally, this is a software issue. In this case, try restarting the handle or re-upgrading. If it still can’t be recovered, it needs to be repaired.

4. RichAuto A18 handle can’t read U disk or read error

1) When the user performs machining using the USB flash drive, the system prompts “There is no item in this direction”. Check if the U disk file system format is FAT32. If not, replace the u disk or re-set the U disk format.

2) Also, the capacity of u disk may be too large, and there is a problem with the handle reading. It is recommended to try to use a USB flash drive with a capacity lower than 8G.

3) If there is a problem with the USB interface of the USB flash drive or the handle, replace the USB interface. Temporary workaround: Copy the file to the handle using the black USB cable.

4) If the program contains illegal characters similar to the non-standard G code, the system will interrupt processing if it is not recognized. It is recommended to use professional simulation software to check if the program has illegal characters and delete them.

We specialize in providing you with high-quality CNC controller and related accessories for cutting, milling, engraving, etc. We support a global fast delivery service for your order. And you could also visit our store in the Aliexpress.com NewCarve store.

If you have any questions, please feel free to contact us:

Email: icnccontroller@gmail.com

Messenger: +8618820192009

WhatsApp : +8618820192009